![]() 1st Battalion 22nd Infantry

1st Battalion 22nd Infantry ![]()

SGT Terry Kotschwar

Memories of a Cold War Warrior

Part Two

|

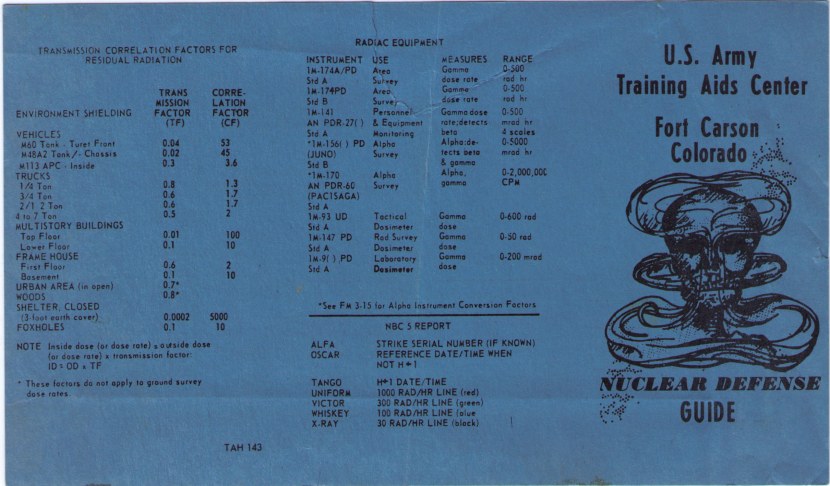

Training aid, dated 1 Jan 1975 |

|

The Green Chip Award Given by the Commanding General |

I got my first Green Chip Award

in 1979 after passing the IG Inspection for the final time. I

think I should have got it the first time

when I was up for three days the day after graduation from TAMMS

(The Army Maintenance Management System) School.

I passed that inspection and I will tell you, they didn't have a

prayer before I redid their books. I still have it from the

CG...Job Well Done.

My commanders weren't really big

on awards, promotions or acknowledgements. I know that Lt. Lee

was supposed to put me

and Kenny Davidshofer in for an Arcom, but he drug it out and we

never got it.

We had a unit lose 11 men (not

sure of the actual number, but I was thinking it was everyone on

board) in a track that plunged down a ravine

killing everyone on board. They sealed the vehicle up and

wouldn't let anyone look inside it. That is one reason I turned

on my lights

when I lost contact with the vehicle ahead of me during a

tactical operation while driving an APC. It was nighttime, the

dust and dirt was like

that on the moon when in the summer months. You occasionally lose

sight of that little 3/8 wide by 4' red tail light on the APC in

front of you

at night. I told the TC that I couldn't see and pulled up. I told

him that I remeber the spot we were in and that there was a drop

off

near where we were. I told him I had to turn on the lights to

see. I ok'd it and I turned them on. We were one vehicle width

off the path

and directly next to the drop off. I was glad and so was the TC.

We didn't tell the others because we didn't want them to worry,

but it was hazardous all the same, even in peace time. We lost a

lot of people in a peacetime Army that never were given

recognition for their contributions.

We were in the new barracks at

the North End of Fort Carson. It was across the street from the

Battalion and the Chapel.

It was down the street from the PT field and next to 1st Bn 11th

Infantry. We bartered with 1/11 and on rare occasions used some

of their equipment,

mechanics and supplies to complete our missions. You either

worked together or suffered the consequences. We had a really

good system.

I felt like Radar O'Reilly sometimes in that I had to utilize the

"network" (we refused to call it the Black Market) to

get what we wanted.

I am not sure that the officers ever knew about the network, but

they had to. I think they just felt if it wasn't broken don't fix

it and allowed us

to work our magic. Anyway, we had most of the post on the net

through various people knowing certain people, etc. We didn't

have PC's,

computers to keep all our items recorded or to search the

internet like today. We had a FISH. A microfische system for

which I would get

new sheets of part numbers that had NSNs (National Stock Numbers)

on them so I could order parts. One month you might find

that the differential or some other part you needed was no longer

an order item, but it was essential to keeping your vehicles in

working order,

so you had to adapt and overcome the problem situation. We always

overcame any obstacle, because we were good at scrounging

or modifying one item to fit another vehicle. Sometimes they

weren't made for that vehicle, but the mechanics would

"adapt" them to make them workable.

We had a dedicated group of

people to work with. I remember we had a track (APC) go down in

the field and we used the M578

to pull the pack. Davidshofer, Rudy, Swink or Hansen worked on it

all through the night. It was a mess. We didn't have power tools

so everything was hand tools and makeshift lighting. We got the

pack pulled, repaired and put in by breakfast. The only thing we

had to do

was put the fluids in and test it. I cranked it up and it

hyperventillated. The blower was stuck wide open and it was

maxing out on revolutions

and the kill switch wasn't working. At first they would yell

"runaway" indicating that the engine was out of control

and could possibly tear itself apart.

It usually meant that we had to leave the area. Swink watched the

damn thing for a mintue or two and it didn't explode, stop or

change pitch.

It was deafening hurting your ears and just whining like a dying

beast trying to escape. Swink grabbed a seat cushion from

somewhere

and put it over the air intake and it finally choked out and

quit. Not sure what the problem was but we couldn't shut it off

inside the track

and the linkage was stuck open. Swink was never one that showed

much emotion and he (like most of the mechanics) could fix

anything.

He was stationed in Korea prior to coming to our company and

perhaps he just had the real life knowledge that we youngsters

just didn't have yet.

We fixed the problem and got the track back into service. One of

many daily tasks that go unseen except by those who do the work

and just keep things running. Results are what are noticed, not

how they come about. We constantly gave positive results and

people just left us alone

to do our work because it wasn't broken.

Track pads came in large crates

when you could get them. They were not really a critical red line

item, but were required for a track

to make it to 100% compliance. We traded, bartered and litteraly

swiped pads for vehicles to at least meet the percentage required

for compliance.

You had to have so many percent of "good" pads on the

vehicle to make it acceptable. I remember calculating the number

of pads required

to make all my vehicles pass inspections and then took good pads

off new tracks to make older ones pass inspection. It was a

balancing act

all the time. I kept track of my expenditures and never broke the

bank buying more than I was allocated and I was always able to

keep my vehicles working.

M113 APC of Company A 1/22 Infantry

(Track No. A-24)

Driver is Terry Kotschwar

The trim vane is missing off

this track (A-24) because I think (and I know it doesn't look

like it) that the track was just painted again.

Most of the imperfections were from the damage to the photograph

I think. The pads that would have been located at the bottom

front edge

were taken off to add to the right side track. I always scrounged

two new pads just in case. If I remember right, between each

section of track

is a log rod or pin that has a locking nut attached to the

inside. You locked the tread or track on the opposite side using

a pair of latterals

which were long aluminum shafts which had a push button at the

top. Your could push the button on the anchor or non-repaired

side of the vehicle

and then, after you removed one pin between two sections of

track, you could get the track sections to move forward or

backwards

on the final drives or the cogged wheels at the front of the

track. The sections were extremely heavy and inveriably they

would not fit together easily

and usually had to be coherced with a sledge hammer, tanker bar

or some other tool to make it willing to cooperate and fit

together.

Surrounding the pin that went through the track section was a

rubber bushing that always wore out and was the primary reason

for replacing a track section.

You always inspected your track spacing with a metal gauge that

went from the center line of one pin to the center line of the

second pin.

If your spacing between the two was excessive it could lead to

failure and that could be disasterous when hurling a vehicle that

weighed

about 11-tons along a tank path to have it suddenly throw a

track. Not Good.

The main problem is that you

needed to have a certain number of track sections out of

tollerance in order to warrant a work order

to have replacement sections ordered by Battalion or they

wouldn't send in an order. The order could take over a month to

fill and that means

a red-lined (useless or dangerous) track. You anticipated needing

sections and "adjusted" your count to allow enough time

for your repair parts

to come in before you actually really needed them. There was

ALWAYS a flurry of requests prior to IG Inspection time which

upsets

the Supply/Demand balance making for some very unhappy people.

Experience taught you to order "off season" and store

it until

you actually needed them and a week or so prior to the IG you had

a track breaking party and all the drivers, TC's and crews

were on the hill side breaking track. Having little use on a set

of new treads helped IG inspectors pass your vehicles and made it

hard for them

to want to look for failure items. Another thing learned from

experience. Never tick off the IG. They have the power, time and

need

to find something wrong with a vehicle if you make them mad. You

always have hot coffee and donuts and a clean desk and chair for

them to sit in.

Never hurts to plan ahead. I never failed a single IG inspection.

Battalion was the only unit that

had a steam cleaner and you paid dearly to get to use it, but it

was the only way to get Petroleum,

Oil and Lubricants (POL) out of the engine and interior

compartments of a tracked vehicle. You removed everything inside

the track.

All the paperwork, tools, seat pads and anything else that you

didn't want to soak. You put on an old set of fatigues, boots and

then took

the bottom plates off the track and then steam cleaned

everything. It took a long time to do and every member of the

crew was involved

(except the slackers) to get your track ready for inspection.

Keeping in mind that everyone wanted the steam cleaner, the

bidding got pretty steep,

but if you knew where some of the bodies were buried, you moved

up the ladder pretty fast. We had lots of body maps, so to

speak...just kidding!

A broken trim vane was a dead

line item. Not that we ever put one in a lake or were ever going

to plan to, they would surely deadline a track

like no other item except a neutral safety switch or ramp cable.

The trim vane was only a piece of plywood but should you ever

want to float an APC

you need a trim vane to get into the water, otherwise the wake of

water would over take the track, fill it up and send it to the

bottom

like a bucket of mud. Every once in a while a driver thought he

was driving a M-60A2 tank and try to knock over a cedar tree that

grew everywhere

down range at Carson. They always broke the damn trim vane and

you could get a replacement (maybe) but it always had to be

painted

the tri-camoflage color. It was always sent in dark green from

704th and wasn't acceptable for inspection. The drivers usually

took the trim vanes

off the track in anticipation but always lost the nuts, bolts and

screws for the new one, which had to be ordered individually.

There were a lot of parts to keep track of and usually they

failed to keep the original parts or damaged them while taking

them apart.

We had to keep a specific nut, bolt or washer for that purpose

because inspectors loved to gig you on having the wrong parts on

a vehicle.

I had extras. I kept neutral safety switches in my desk drawer

and the mechanics knew not to let a crew memeber put them in

because

they always burnt them up somehow. Without the switch the engine

wouldn't start and that prompted crew members to become creative

in bypassing the wiring to make the engine start. Mechanics were

not very tollerant with people "Modifying" standard

wiring, unless of course,

they did the modifications.

Sergeants run the Army, but Mechanics get you to where you need to go...

|

Kenneth John Davidshofer Company A 1/22 Infantry "Without Kenny, I would not have

been nearly as efficient, as we were as a unit. Terry Kotschwar - 2010 |

Below:

The rather gruesome illustration on

this training aid is a reminder of the ever-present reality

that Soldiers of 1/22 Infantry had to live with during the 1970's

and 1980's. Nuclear war was a very real

possibility during those years, and 1st Battalion consistently

trained in preparation for it.

Formation of M-60 tanks in Germany,

during Reforger '77.

List of all the vehicles in Company A 1/22 Infantry "Don't ask me why I documented

this information, but I always liked stats. Terry Kotschwar - 2010 |

|

Sign posted in the motor pool of Company A 1/22 Infantry

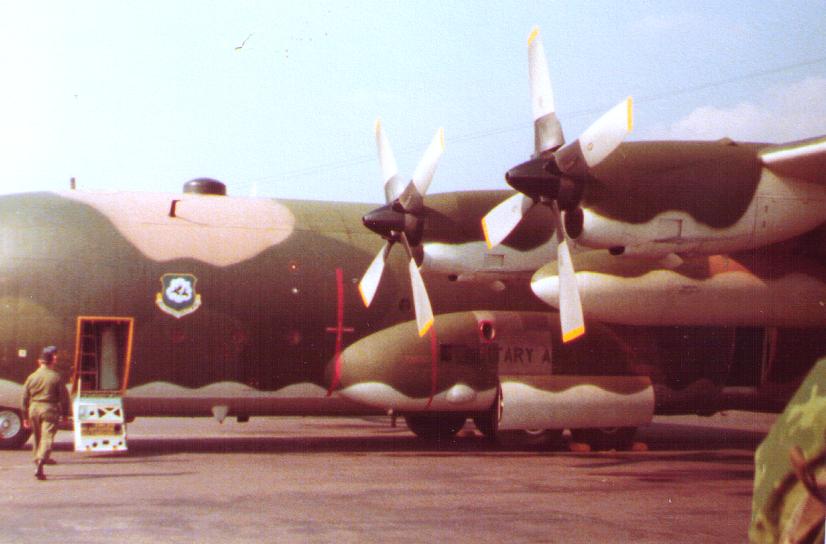

C-130 Hercules transport at "Pete

Field" 1977.

C-130's and C-141's were the main aircraft used by 1/22 Infantry

during the many times they were place on alert while at Fort

Carson.

All photos courtesy of Terry Kotschwar

Home | Photos | Battles & History | Current |

Rosters & Reports | Medal of Honor | Killed

in Action |

Personnel Locator | Commanders | Station

List | Campaigns |

Honors | Insignia & Memorabilia | 4-42

Artillery | Taps |

What's New | Editorial | Links |